With an end goal of preserving and protecting assets and infrastructure, MEnD specialises in the inspection of coatings, as well as remediation strategies and specification development.

About MEnD

At the heart of MEnD’s mission is the life extension of assets and infrastructure to help shape a sustainable built environment for future generations. In order to realise this goal, the business focuses on the inspection of assets, as well as the recommendation of works required to remediate and protect them.

The consultancy also provides ongoing monitoring of structures and devises maintenance programs to ensure clients stay on top of their asset’s condition.

Coating inspection expertise

Coatings are one of the most extensively used methods for the protection of concrete-and-steel structures against degradation. Like all materials, though, coatings deteriorate over time and, depending on the environment and other conditions, need to be maintained at regular intervals. This process begins with an inspection, which can involve failure analysis, expert witness work and corrosion detection using AI.

MEnD’s engineers and consultants have both technical and practical experience in conducting such inspections, allowing them to determine the condition of existing coatings, as well as their

likely life expectancy. This expertise spans multiple sectors, from marine, mining and defence to building and facade, energy and infrastructure, and can be undertaken at any stage of the asset’s

lifecycle, whether it be initial application or during regular maintenance.

Failure analysis

When coatings fail, the impact on asset integrity and operational costs, can be significant. To

mitigate these challenges, MEnD conducts in-depth failure analyses, identifying root causes, such as material selection issues, application deficiencies or environmental factors. This process typically involves:

Obtaining background info

By gathering background information on the coating type, application procedures, service history and environmental conditions, MEnD’s engineers are able to gain a comprehensive understanding of the circumstances surrounding the failure.

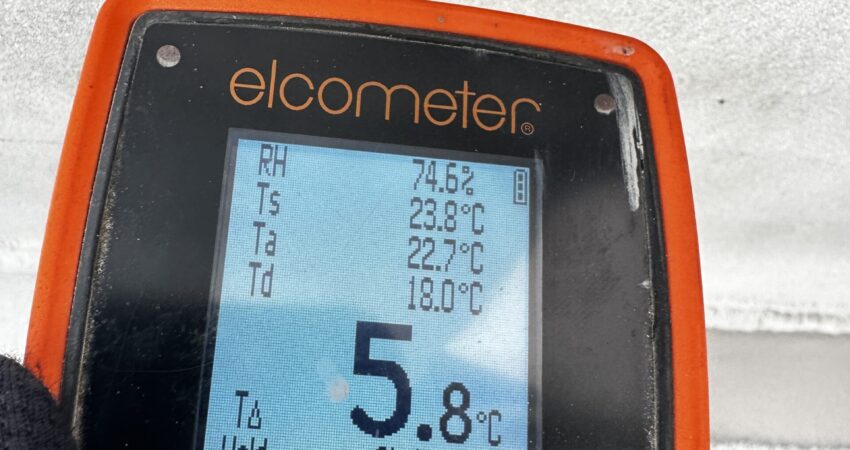

Inspection and data collection

Conducting a detailed examination of the failed coating allows for the identification of defects.

While this is sometimes done with the naked eye, modern technologies – such as drones, ROVs

and laser scanners – are now used to document defects. iPhones and iPads can also assist with

photogrammetry – a process whereby data is derived from photographs and converted into 3D

models, providing enhanced visualisation, not only for the engineers but also for the client.

Sample analysis

Taking samples of the failed coating is sometimes necessary for further analysis. MEnD’s dedicated

laboratory allows its specialists to undertake both destructive and non-destructive testing methods

to assess properties like adhesion, thickness and chemical composition.

Expert witness work

An expert witness is typically a highly experienced coating inspector who can analyse the coating and use their specialised knowledge to interpret the causes of coating failure. The expert witness is able to present findings from their inspection, explain technical details and offer professional opinions. This helps clients understand complex issues and make informed decisions regarding remediation and maintenance.

AI corrosion detection

MEnD is an early adopter of advanced technology, integrating AI-powered corrosion detection to enhance inspection accuracy and efficiency. Using machine learning and image analysis, the team identifies defects, tracks degradation and predicts failure risks, allowing for proactive maintenance and improved asset longevity.

Remediation strategies

MEnD’s reporting system provides clients with information regarding the condition of their asset. Reports outline the causes of the coating failure and recommend corrective actions.

Remediation strategies consist of practical solutions to restore coating performance, prevent the recurrence of failure and deliver long-term durability. The team’s technical expertise also ensures assets remain compliant with the highest standards.

Coating specification

Well-crafted coating specifications are critical to asset protection. MEnD offers expert reviews of existing specifications, ensuring they align with industry best practices and project requirements. The team also develops tailored specifications that consider environmental conditions, substrate preparation, application methods and quality control measures.

Coating product trials

Prior to application, MEnD undertakes trials to test the effectiveness of the coating. These trials are essential for ensuring that the coating will perform well under specific conditions and typically involves:

Surface preparation

The surface is thoroughly cleaned and prepared to ensure optimal adhesion of the coating.

Coating selection

Coatings are chosen based on environmental conditions, substrate type and performance requirements.

Application techniques

Various application methods, including spray, brush and roller, are tested to assess film build, coverage and ease of application.

Curing and inspection

Once the coating has cured in controlled conditions, it undergoes visual inspection and is tested for thickness and adhesion.

Performance testing

Coated surfaces are tested to evaluate their resistance to corrosion, abrasion and other damaging factors.

ABOUT THE EXPERT

Patrick Stevens

Senior Coatings and Corrosion Consultant, MEnD

Leading MEnD’s coating inspection services is Senior Coatings and Corrosion Consultant Patrick Stevens, an ACA-certified Corrosion Technologist and NACE 3/AMPP Senior Certified Coating Inspector. Patrick holds a Diploma of Quality Auditing and has 20 years of industry experience.

Patrick started his career ‘on the tools’ as a blast and painter. This practical experience allowed him to progress his career into coating inspection, large-scale quality control, quality assurance and asset management. His expertise underpins MEnD’s commitment to delivering best-practice solutions.

ACA: Australasian Corrosion Association

NACE: National Association of

Corrosion Engineers

AMPP: The Association for the Advancement of Materials Protection