Duratec and MEnD transform asset management with Flinders Ports, using digital tools like photogrammetry and BIM for safer, smarter marine infrastructure.

Flinders Ports is revolutionising marine infrastructure inspection, maintenance, and management through a strategic partnership with Duratec – an alliance built on innovation, trust, and long-term vision.

Over the past 2.5 years, Duratec has delivered more than $10 million in remediation and inspection services under a Master Services Agreement (MSA) with Flinders Ports. Prior to the MSA, works were awarded through competitive tendering, which ultimately led to Duratec being engaged as a preferred partner under the MSA.

The transformation started with condition assessments of underwater piles and footings. It has since expanded to include steel, concrete, and water main pipe repairs across berths, beams, and workshops.

The first major Duratec project was at Inner Harbour Adelaide in 2019, where the team remediated berths 18 to 20 in three stages. The structure required extensive rehabilitation to ensure safe and effective future operations.

Jonathan Barrett, Duratec’s State Manager for South Australia, played a key role in strengthening

the client relationship. “What began as a focused remediation effort quickly evolved into a broader, more impactful collaboration,” he said. “Thanks to our team’s professionalism and commitment, we’ve built a trusted, long-term partnership.”

Digital inspections redefining marine asset management

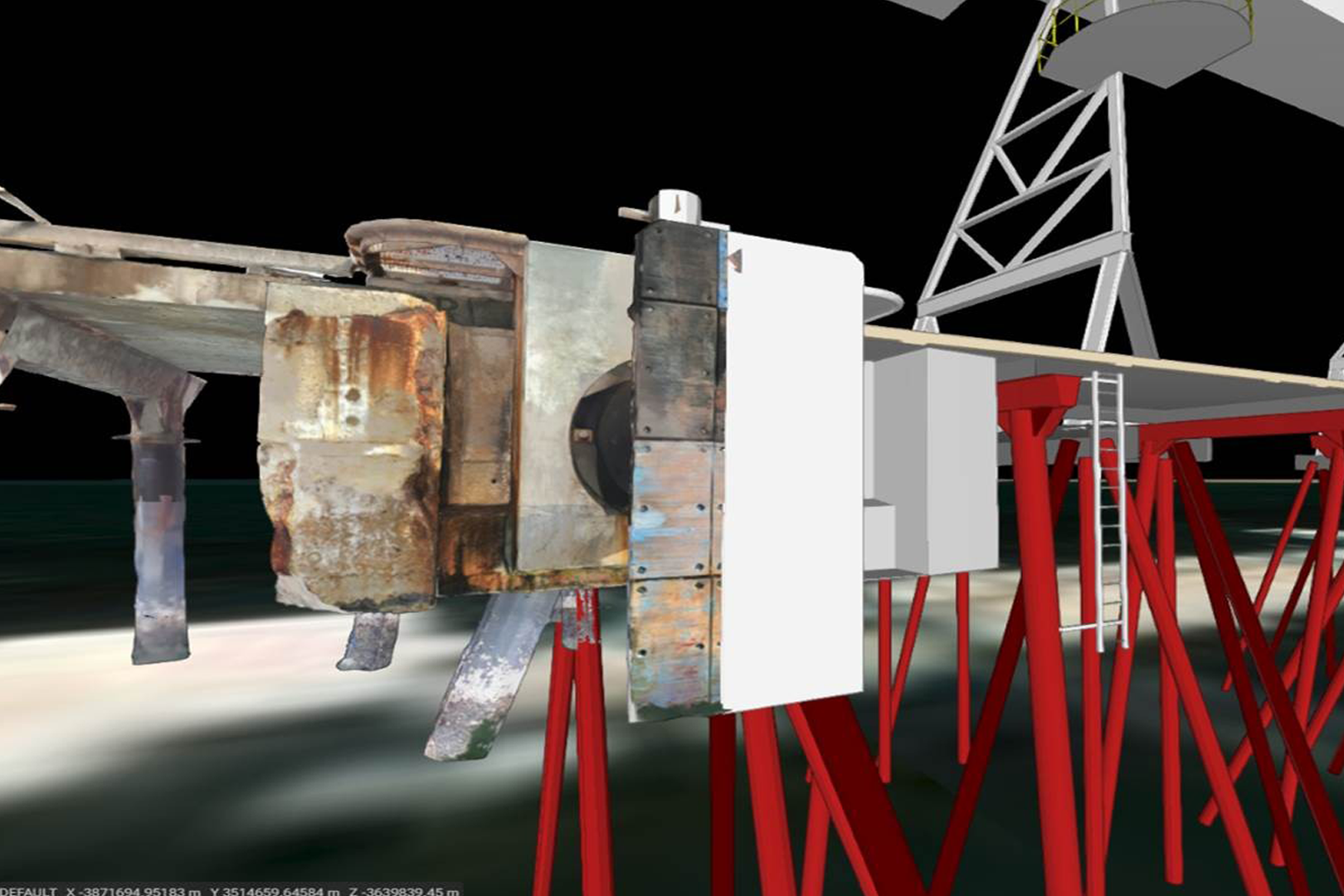

The real breakthrough came with the adoption of high-resolution photogrammetric reality modelling.

This is a technology that enables inspections of port infrastructure in a desktop setting. MEnD (a Duratec company) has been instrumental in bridging traditional asset management with digital innovation, working closely with Flinders Ports project managers and engineers.

Using advanced tools such as aerial drones, drone boats, 42MP photogrammetry cameras, and our in-house developed ‘SLAM-CAM’, the team has delivered unmatched digital inspection and condition assessments.

To date, MEnD has delivered 1mm resolution above water reality modelling for five berths, high-resolution multibeam surveys, capturing pile footings and seabed geometry with exceptional clarity, and terrestrial laser scanning to monitor a rock revetment. This high-fidelity modelling has enabled stakeholders to assess structural conditions both above and below the surface.

“Working within the marine environment has its risks and challenges. Working at height and on or near the water, and the safety risks start to stack up,” said Jane Hogben, Digital Assets Lead at MEnD. “On top of that, accessing these areas isn’t just tricky, it’s costly too,” she said.

Photogrammetry models allow teams to conduct detailed inspections offsite, significantly reducing those risks. They’re identifying cracks, spalls, corrosion and mapping far more accurate and detailed defect extents than you could document during an on-site inspection. In addition, detailed desktop inspections that drive targeted on-site testing where required, ultimately delivers far more valuable investigations into asset condition and diagnoses.

“However, it’s not just about the inspection. Capturing and presenting everything in a holistic environment gives unparalleled context for stakeholders,” Jane said. “Photogrammetry models take it further, enabling offsite inspections that reduce risk while mapping defects with unmatched accuracy.”

The power of IIM (Infrastructure Information Model) and GIS in port infrastructure

These datasets are used to back-model an as-built IIM (Infrastructure Information Model) in many places providing holistic visualisation and oversight of asset hierarchy and condition. IIM modelling (an evolution of the Building Information Model principles for non-building assets and a conceptual adaptation of BIM for horizontal assets) is being published in the Port’s on-premises GIS system with controlled user access to allow engineers to update asset information as required.

MEnD documents IIM components that are aligned with the Flinders Ports asset hierarchy identifier, which will later enable dynamic integration with the port’s asset management system. This will make it easy to track repairs, defects, and history, all into one simple and accessible front-end application.

Flinders Ports are also using the cloud-based 3D spatial platform Annoview, supported by Skand.io, to host reality modelling and defect assessments for secure, shareable digital scopes of work. This enables virtual site visits for tenderers, improving pricing accuracy through better material estimates, labour planning, and access planning.

Managing assets smarter and safer

MEnD’s digital platform goes beyond inspections; it supports the entire asset lifecycle. From identifying defects and planning repairs to tendering works and tracking completions, it enables long-term strategies through reinspection cycles, helping teams monitor deterioration and reprioritise using real data.

In challenging marine environments, where tidal conditions, restricted access, and strict safety protocols complicate inspections, this approach reduces downtime, improves accuracy, and enhances safety. By minimising manual inspections and enabling targeted interventions, it also drives cost efficiency and supports sustainable asset management.

What else can MEnD offer? By helping clients navigate the platform and transition seamlessly from paper-based workflows to digital asset management, MEnD enable smarter, more connected operations.

With asset management strategies becoming mandatory across Australia, Flinders Ports is setting the benchmark digitally, strategically, and collaboratively. This case study shows what’s possible when technology meets trust and partnerships are built on shared goals.