Duratec Harnesses Innovative Technology to Tackle Major Construction Challenge

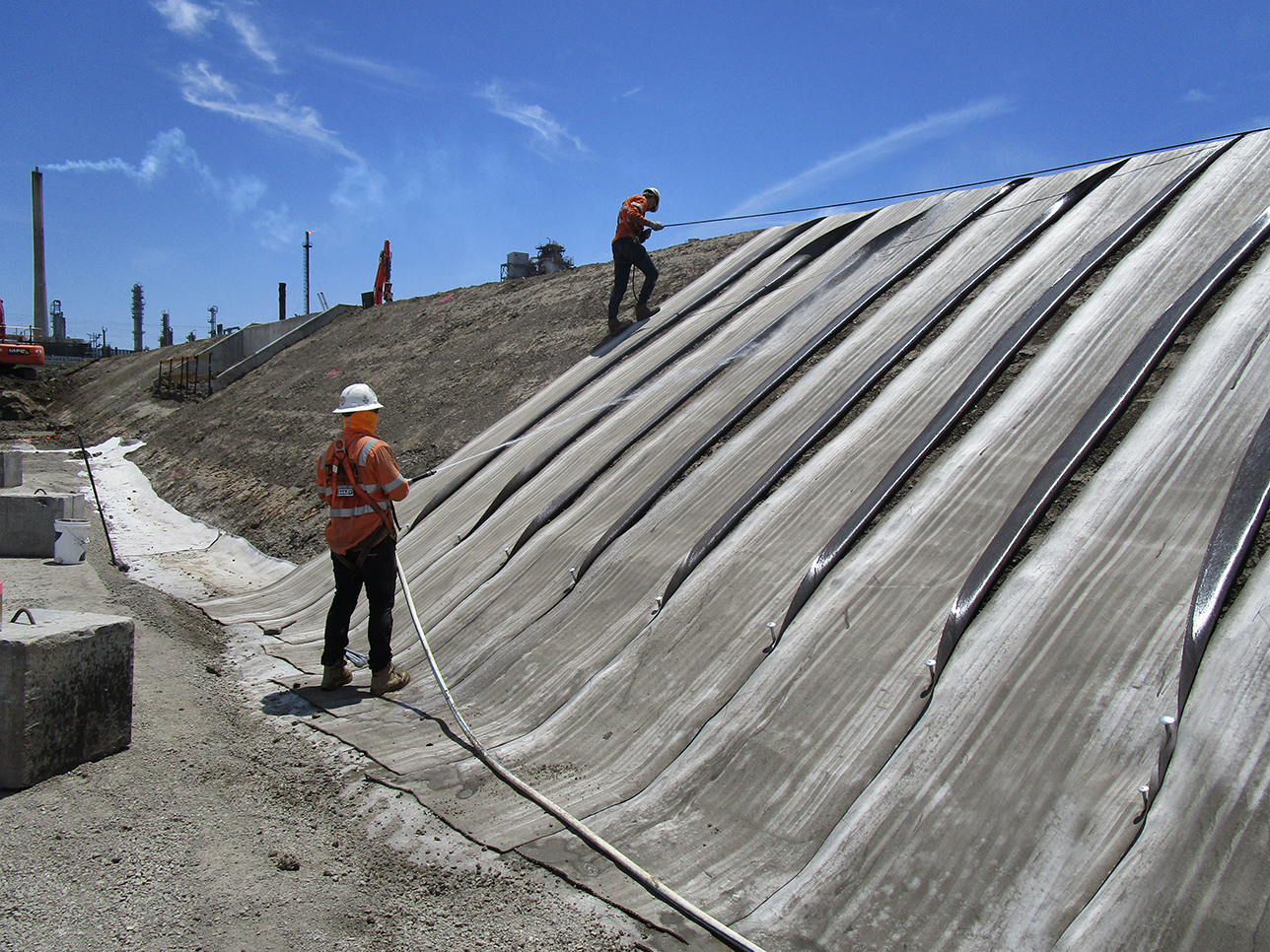

Duratec engineers have successfully deployed a cutting-edge Geosynthetic Cementitious Composite Mat. Commonly known as Concrete CanvasTM, the matting is a sustainable and cost-effective solution to a complex construction challenge.

Almost like magic, this flexible, concrete-filled geotextile hardens upon hydration to form a thin, durable, and waterproof concrete layer. The team selected this spellbinding material over traditional methods to meet the client’s requirement for an unobstructed line of sight along the perimeter of their property; the perimeter was a steep, heavily vegetated slope, making conventional excavation and lining techniques impractical.

The Concrete Canvas (CCXTM), part of the GCCM/B family, was identified as the ideal slope-stabilisation solution due to its slim profile, rapid installation, and long-term durability.

Duratec deployed a specialised excavator to install the canvas, designed to safely navigate the steep terrain. This equipment enabled efficient vegetation clearance and minimal topsoil removal, preserving the slope’s integrity and reducing erosion risk.

Once the slope was cleared and prepped, engineers cut and positioned the CCXTM rolls, anchoring them securely before uniformly hydrating the surface. Within 24 hours, the canvas transformed into a walkable concrete layer, an impressive feat of engineering and efficiency.

By embracing this innovative technology, Duratec achieved faster installation, reduced costs through minimal labour and equipment, and enhanced performance with immediate slope stabilisation and erosion control. The approach also delivered significant sustainability benefits, including lower water usage, minimal soil disturbance, and a reduced carbon footprint by using less cement than a traditional concrete pour.

Image courtesy of Geofabrics Australasia