Duratec carried out an essential revival of Newcastle’s 130-year-old Fernleigh Tunnel – partnering heritage restoration and modern technology to preserve history for future generations.

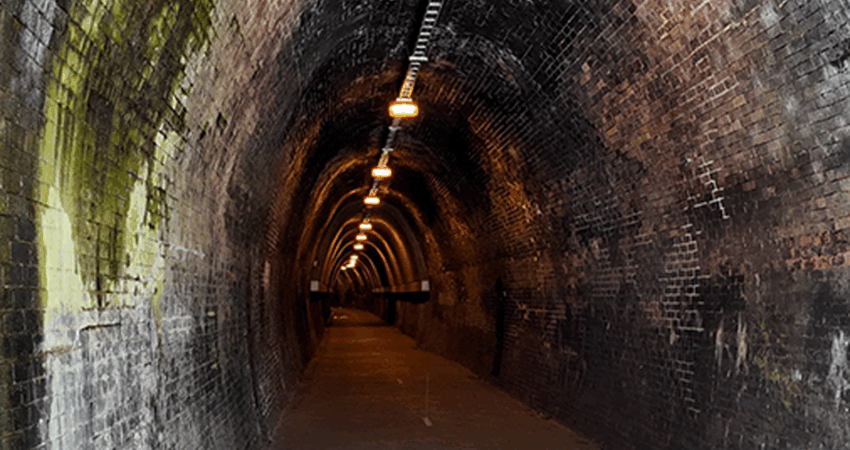

The Fernleigh Tunnel has stood for over 130 years. Nestled between Adamstown and Belmont in Newcastle, it was once a coal transport route and is now a key part of the 15-kilometre Fernleigh Track. In 2025, Duratec was engaged by the City of Newcastle to renew this heritage-listed structure.

Timeline of a tunnel

Built in the early 1890s by the Redhead Coal Company, the Fernleigh Tunnel linked Lake Macquarie’s coalfields to Newcastle’s port. The tunnel was opened in November 1892 following three years of construction and £90,000 in costs (more than $16 million AUD today). The 181-metre tunnel was carved through a ridge separating southern collieries from Adamstown and the Great Northern Railway.

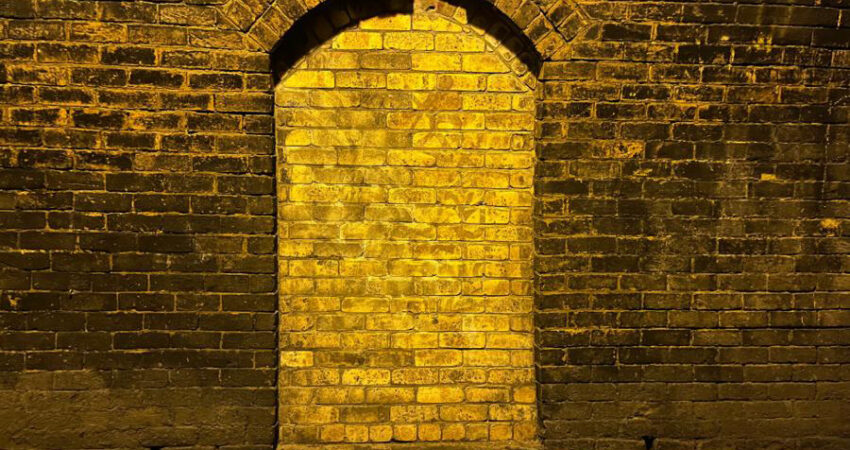

Constructed with hand-made bricks and sandstone capping, its horseshoe-shape highlights the influence of British Engineering that was prominent in the late 19th century. Initially Fernleigh Tunnel was used for coal transport from the Burwood, Dudley, and John Darling collieries, and soon carried miners through as passengers.

By 1910, passenger trains ran to Newcastle, and the Fernleigh Loop was added to ease traffic. Passenger services declined in the 1950s as bus and car transport grew in popularity. In addition to this, the tunnel’s narrow bore hindered railway upgrades.

The line eventually closed in 1992 and was reopened as a cycling and walking path in 2011.

Scope of work

- Installing 80m² of stainless-steel overhead mesh

- Laser removal of 80m² of graffiti

- Applying anti-graffiti coatings

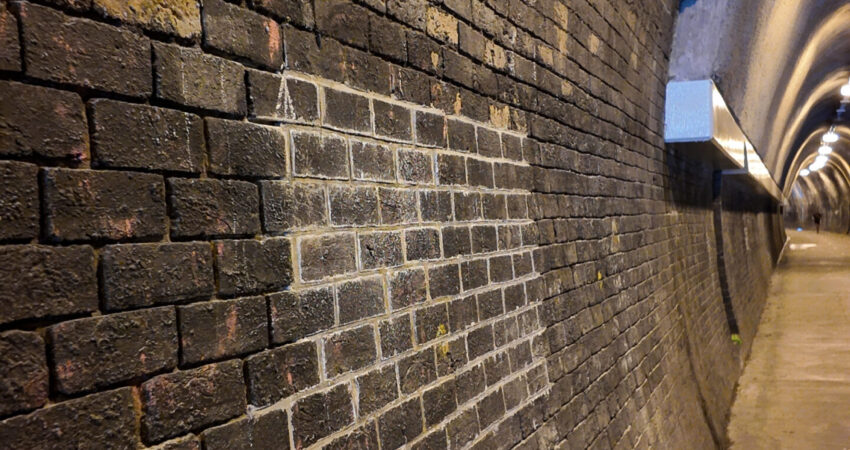

- Repointing 1300m of brickwork

- Removing vegetation

- Constructing eight drainage weep holes

- Installing crack gauges

Leading Hand, Byron Wright described it as “a good challenge,” especially considering that public access had to be maintained. “We couldn’t close the tunnel off at any stage,” he said. “All the works had to be done on one half of the bicycle track at a time.”

Materials: durable feel with heritage aesthetic

Materials were chosen for both heritage compatibility and environmental resilience:

- 316 Stainless Steel Mesh: Non-corrosive and strong, the 25x25mm mesh protects users from falling debris while brightening the tunnel

- Drainage Weep Holes: Made with slotted 80mm PVC piping, each hole extended 1.5m and was wrapped in geotech fabric to ensure effective drainage

- Moisture-Tolerant Mortar Mixes: Selected to match heritage requirements and withstand damp conditions

Craft and tech side-by-side

The project showcased traditional craftsmanship alongside the use of modern tech. Brick repointing required heritage-specific mortar and colour matching and was performed by dedicated tradespeople.

“They’re not your basic bricklayers,” said Project Coordinator Jamie Meaclem. “They’re real professionals who have a passion for their trade.”

To remove graffiti, laser technology was implemented to avoid damaging the brick work. “Laser cleaning vapourised the paint into a fine dust,” Byron explained.

Constraints and challenges

Working on a heritage site in a live public space posed some unique challenges:

- Heritage Constraints: Repointing required matching aged mortar colours

- Public Access: The tunnel remained open, with work done on one half of the track at a time

- Weather: Over 350mm of rain complicated coating application and increased water ingress; eight weep holes were installed in affected areas

- Workflow Adjustments: Crews shifted to dry areas and returned to wet zones after dry spells

- Site Access: The shed was 200m from the tunnel, and vehicle access was 750m away. Rain created mud, requiring traffic control and escorts

- Night Shifts and Antisocial Behaviour: All work was done at night. “You get interesting people in the tunnel at 3:00 in the morning,” Byron joked

Despite these hurdles, the project was completed safely and on time.

Community engagement

Duratec and the City of Newcastle kept the community informed through numerous doorknocks and letter drops. While on-site, the team was transparent and approachable and explained the project to passersby. Noise was managed with generators switched off by 10pm and with louder tools being used earlier in the day.

Safety and sustainability benefits

Beyond aesthetics, the project delivered structural and safety improvements. Brick repointing strengthened the tunnel and overhead mesh prevented brick falls. Weep holes were also installed to address moisture issues.

“It’s about maintaining the structure and extending its life,” Jamie noted.

The community impact was also significant. “I used to ride through the tunnel myself,” Jamie shared. “Seeing it enhanced was the most meaningful thing for me.”

Byron added, “If we preserve structures like this, they can outlast us. That’s sustainability; not just in materials, but in values.”

Preservation for the present

The Fernleigh Tunnel Renewal is an ideal model of heritage preservation supported by innovation, and community collaboration.

“It’s nice to have heritage brickies and modern restoration technologies on the same project.” Byron said. “New and old skills working side by side.”

With the works complete, the tunnel stands as both a historical relic and a symbol of sustainable infrastructure.